Before you decide to insulate your house – choose thermal-insulation class A++

- Details

The choice of thermal insulation directly impinges on the maintenance costs of the house. Here are a few tips on what to look out for when choosing thermal-insulation material.

Before you decide to insulate your house – choose thermal-insulation class A++

The choice of thermal insulation directly affects the maintenance costs of the house. Just like buying a heat pump, an energy-efficient furnace, or photovoltaic cells, this is an investment which pays off over time. Here are a few tips on what to look out for when choosing thermal-insulation material.

The heat-transfer coefficient

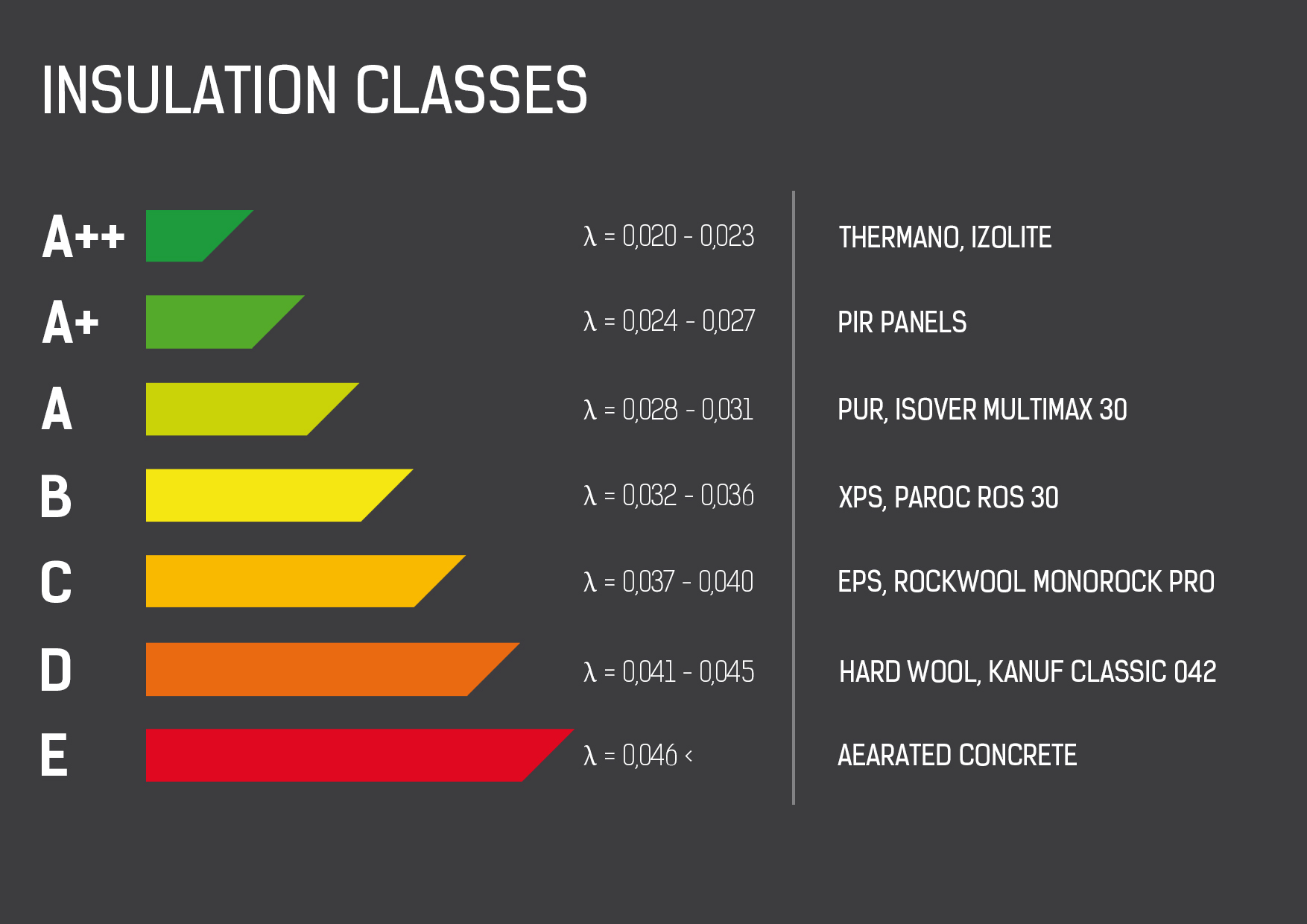

When buying a TV set, we pay attention to the number of inches, when choosing a computer we look for the amount of RAM or the type of processor, while in the case of purchasing materials for home insulation, the key factor will be lambda (marked with the symbol λ). The lower the value, the better the insulating properties of the material.

From the materials commonly available on the market we can pick out

- PIR panels (λ=0.023 W/mK)

- XPS Styrodur (λ=0.032 W/mK)

- EPS polystyrene (λ=0.036 W/mK)

- Mineral wool (λ=0.040 W/mK)

On this list, the best performers are hard PIR panels in Thermano gas-tight linings, with insulation class A++, which provide 50% better thermal insulation than the XPS panels, which are second on the list. The quoted lambda values might vary slightly, depending on the type of product.

*PUR without gas-tight lining

**The warmer types of aerated concrete

Not all Lambdas are equal

A few manufacturers cite the ageing lambda, which relates to thermal-insulation properties after the installation of the material in the facility. The majority quote the “declared” lambda, i.e. the value for the product immediately after leaving the production line. The manufacturer of PIR Thermano panels marks its product with ageing lambda, which allows you to reliably predict how effectively the material will protect the house from heat and cold.

Moisture resistance

How many times have we seen a construction site with partially installed thermal insulation? This is a common sight, as it is very rare for a contractor to finish the work in one day. What happens to the material if it is exposed to moisture? It is not difficult to predict. While EPS polystyrene, XPS Styrodur, and PIR panels do not pose a threat. mineral wool, be it rock wool or glass wool, absorbs water, and this permanently changes its thermal-insulation properties.

The principle of operation is simple - the presence of water causes a partial replacement of the insulating material lambda with water lambda, which, in the case of wool, is up to 15 times worse (λD 0.040 vs. λ 0.600). Therefore, a very-important parameter is long-term water absorption. The higher the coefficient, the greater the risk of losing insulation properties.

Material thickness

The more insulating the material, the smaller thickness will be required to meet building standards. Every few years, these standards are tightened, and this requires thicker and thicker insulation layers. That is why modern construction is based on materials which can be installed not between rafters, but onto rafters.

Such a solution does not require lowering the ceiling in the attic, but first of all it allows one to get rid of the problem of thermal bridges, i.e. interruptions in thermal insulation. Thermano panels are the most-commonly used material for rafter insulation.

Advertisements for various thermal-insulation products are convincing in terms of price, but less often in terms of lambda coefficient.

If you are building a house over a period of years, it is worth sparing a moment to take a closer look at the properties of the materials sold by the manufacturers. It might turn out that by investing in the purchase of material and its installation, we will pay heavily for a product of questionable quality, which will make us liable for multiple building-maintenance costs.

The main categories of materials for the thermal insulation of buildings

The choice of thermal-insulation materials is so wide that each combination will be characterised by a certain standardisation. Below are presented the most-commonly used product categories, i.e. PIR panels, polystyrene, Styrodur, and mineral wool (with the standard division into lightweight [up to 40 kg/m3] and heavy [over 100 kg/m3].

Your reply