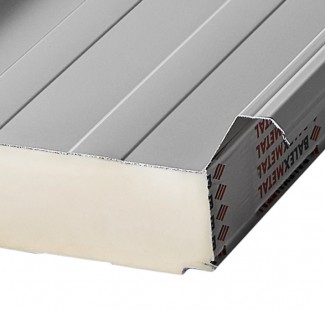

PIR STANDARD sandwich panel (polyurethane core)

WHEN THE INSULATION LEVEL AND PRICE MATTER

The rigid polyurethane foam core provides excellent thermal insulation for buildings. This comes from an excellent thermal conductivity coefficient, λ = 0.022, unparalleled by any mineral wool or EPS sandwich panel.

Attributes

| Name | PIR STANDARD sandwich panel (PU-PIR-W-ST) | |||||||

| Core | Rigid polyurethane foam, PIR (nominal apparent density: 40 kg/m3) | |||||||

| Cladding thickness [mm] | 0.4 / 0.5 / 0.6 / 0.7 | |||||||

| Steel grade | S250GD, stainless steel (1.4301) (inner cladding) | |||||||

| Coats |

SP Polyester Gloss 15μm,SP Polyester Gloss 25μm, SP Polyester Mat Pearl, Food Safe PVC(F), Stainless steel, Cesar 55 |

|||||||

| Effective width [mm] | 1000, 1100 | |||||||

| Overall width [mm] | 1020, 1120 | |||||||

| Panel length [mm] | 2000 to 18000 | |||||||

| Core thickness [mm] | 40 | 50 | 60 | 80 | 100 | 110 | 120 | 130 |

| Weight [kg/m2] | 10.3 | 10.6 | 11.1 | 11.8 | 12.6 | 12.9 | 13.2 | 13.5 |

| Insulating efficiency, UC [W/m2K] | 0.59 | 0.45 | 0.36 | 0.27 | 0.22 | 0.2 | 0.19 | 0.17 |

| Fire resistance | NPD | NPD | NPD | NPD | up to EI 20/up to EW 30 | |||

| External fire performance | FR* | |||||||

| Reaction to fire | B-s2,d0 | B-s1,d0 | ||||||

*Fire-resisting

| Panel length | Panel side | Cladding thickness [mm] | Profiling** | Coat | ||||||

| min. [mm] | max. [mm] | SP Polyester | SP Polyester Mat Pearl | Cesar | PVC(F) | Aluzinc | Stainless steel | |||

| 2000 |

18000 |

outer | 0.5 / 0.6 / 0.7 | L / M / G / 1L / 2L | x | x | x | x | x | |

| inner | 0.4 / 0.5 / 0.6 / 0.7 | L / G | x | x | x | x | x | |||

**Profiling abbreviations:

L - Lined

M - Microprofiling

G - Plain

1L - Clearline

2L - Double Clearline

Panel joint detail

Exposed lock

Panel cross-section

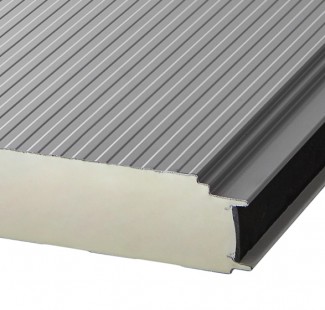

Cladding profile types

Lined (L)

Outer cladding Inner cladding

Micro-profile (M)

Outer cladding

Plain (G)*

Outer cladding Inner cladding

Clearline (1L)*

Outer cladding

Double Clearline (2L)*

Outer cladding

*The thickness of 0.5 mm in G / 1L / 2L profiling from the outside, requires the signing of a statement by the Customer, in which he accepts the possibility of a visible deviation from flatness, being within the permissible tolerance up to 0.6mm / 200mm by EN: 14509.

Colors

Other

STAINLESS STEEL

9010 FOOD SAFE PVC(F)

SP Polyester 25 μm

1003 signal yellow

1015 light ivory

3000 flame red

3011 brown red

3016 coral red

5003 blue sapphire

5010 gentian blue

6005 moss green

6011 reseda green

6018 green yellow

6020 chrome green

7012 basalt grey

7016 anthracite grey

7024 graphite grey

7035 light grey

7040 window grey

7047 telegrey 4

8004 copper brown

8012 red brown

8017 chocolate brown

8019 grey brown

9002 grey white

9005 jet black

9006 silver metalic

9007 grey aluminium

9010 pure white

SP Polyester Matt Pearl 35 μm

3301M brown red

6490M chrome green

7016M anthracite grey

7591M graphite grey

8620M copper brown

8637M chocolate brown

9005M jet black

Cesar 55

7016 anthracite grey

8017 chocolate brown

9005 jet black

9006 silver metalic

9007 grey aluminium

9010 pure white

Attachments

Product declarations and certificates

General catalogues & price lists

Technical catalogues

Manuals

Environmental Product Declarations

Design files

General Terms & Conditions of Sales

Approved:2024-05-29 11:28:06