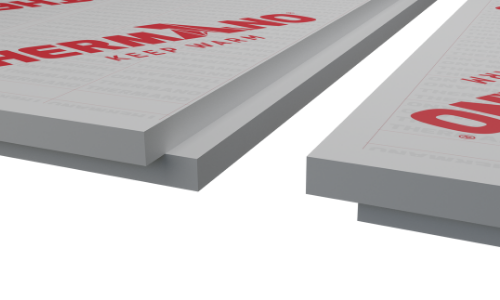

Thermano Floor Pir thermal insulation boards

HIGH STRENGTH AT MINIMIZED THICKNESS

Thermano Floor is an excellent product used for insulation of floor as well as walls and ceilings shuttered. Thermal conductivity λ at the level of 0.022 W/(mK) and compressive strength of 150 kPa i.e. approx. 15 t/m2 are one of the highest parameters on the market. Thermano Floor can be used up to twice as thin as traditional thermal insulators. Owing to that Thermano provides additional gain of space.

High compressive strength is excellent for floor insulation, preventing crackings. Special cladding provides an additional screen for floor heating, which significantly increases its efficiency.

Thermano Floor panels are characterized by:

- Minimized thickness - Thermano Floor can be used up to twice as thin as traditional thermal insulators.

- Extremely good insulation properties - The best thermal conductivity λ = 0.022 W/mK in the insulation class A ++.

- Great strength parameters – Compressive strength of 150 kPa i.e. approx. 15 t/m2 is one of the best parameters on the market.

- Outer cladding - Special cladding provides an additional screen for floor heating, which significantly increases its efficiency.

- Possibility of wall applications in combination with concrete and reinforced concrete.

Attributes

| Name | Thermano Floor |

| Lock (panel joints) types | BASIC, TOP |

| Core | Polyurethan PIR |

| Cladding | Walki Gypsum - multilayer, gastight |

| Total width [mm] | 1200 |

| Modular width [mm] | 1200 (BASIC), 1185 (TOP) |

| Thickness [mm] | 20, 30, 50, 80, 100, 120, 130, 150 |

| Standard lengths, total [mm] | 600 (small panels), 2400 (standard panels) |

| Custom lengths, total [mm] | 2400 - max 5000 |

| Thermal conductivity coefficient, λ [W/mK] | 0.022 - 0.023 |

| Core volumetric density [kg/m³] | 30 |

| Compressive strength [kPa] | min. 150 |

| Tensile strength [kPa] | min. 70 |

| Reaction to fire class | Euroclass F, ref. EN ISO 11925-2 |

Thermano Floor panels are available in two basic size versions: the standard 2400 x 1200 mm panels and the smaller 1200 x 600 mm format. The minimum order for Thermano Floor in basic variants is 300 m2, with completion time of 4-5 weeks. The Thermano panels can also be ordered in custom lengths.

The chief material used in the production of Thermano Floor panels is polyisocyanurate (PIR), secured on both sides with a gas-tight cladding, comprising several polymer layers and aluminium foil.

The high gas-tightness of Thermano Floor panels ensures stability of the thermal insulating parameters over long periods of time, unlike other polyurethane-based materials without the cladding, i.e. spray-applied (in situ) materials.

The Thermano PIR core is formed by polymerisation of its two main components, polyols and isocyanates, with additional modifiers. The PIR core is a closed cell structure, which means that the material is an essential barrier to capillary wicking of the water and steam (water vapour) diffusion.

Thermano Floor panels exhibit excellent mechanical performance, durability, low absorbability and other physical and chemical characteristics which mark the material out for application in even the most demanding construction environments.

Thermano Floor thickness vs. thermal insulation ratings

|

THERMANO |

INSULATION |

HEAT |

|

|

λ=0.023 [W/mK] |

20 |

1.18 |

0.85 |

|

30 |

0.77 |

1.30 |

|

|

50 |

0.47 |

2.15 |

|

|

80 |

0.29 |

3.45 |

|

|

λ=0.022 [W/mK] |

100 |

0.22 |

4.55 |

|

120 |

0.18 |

5.45 |

|

|

130 |

0.17 |

5.90 |

|

|

150 |

0.15 |

6.80 |

|

Panel joint types

BASIC lock (straight edge)

TOP lock (overlapping)

Attachments

Product declarations and certificates

General catalogues & price lists

Manuals

Design files

General Terms & Conditions of Sales

Approved:2024-03-04 08:11:58