How can we build a thermal insulation system for a floor?

Instructions for installing Thermano in floors with underfloor heating systems.

Instructions for installing Thermano in floors with underfloor heating systems.

The thermal insulation of floors is key to the overall thermal improvement of a building. Warm air tends to rise, so thermal insulation at the ground level is essential in achieving thermal comfort in all the rooms of a house. If we need to thermally improve a floor with an underfloor heating system, doing so with PIR-core sandwich panels reduces heat losses directly at the heat source.

How much does the thermal improvement of a floor or flooring cost?

Thermal improvement, or installation of thermal insulation in a new build, is a good investment. Thermano reduces home heating costs significantly enough to achieve a 100% return on the investment in 3 to 4 heating seasons.

*Thermal improvement with the Thermano PIR-core sandwich panels is simple and quick to complete. We can do it without assistance, and without a problem. It is no different from the installation methods used for other thermal insulation materials. It takes no more than a few hours to install a thermal insulation solution in a residential building.

Step-by-step thermal improvement of a floor

The installation of Thermano panels is very quick and simple. It is no different from the installation methods used for other thermal insulation materials. It takes no more than a few hours to assemble a thermal insulation solution for a residential building.

1. To install the thermal insulation, you will need aluminium tape and Thermano panels. It is critical to choose the right thickness of the thermal insulation layer. 80 mm is the standard dimension for residential homes which meets the regulations from the Ministry of Construction. For installation in industrial buildings, especially in cold stores, freezers, or fruit and vegetable storage facilities, the thickness of the Thermano panels should be based on the outline design specifications.

2. Before laying the Thermano system, a lean concrete substrate should be laid, relatively level and suitable for laying a rigid thermal insulation layer. It is recommended to lay 1200 x 600 mm panels in residential buildings.

3. Thermano is laid in a staggered arrangement. The panels are joined with the TOP overlapping lock, which ensures perfect thermal sealing of the assembled layer.

4. The Thermano panel interfaces are additionally secured with the aluminium tape. An alternative is to cover the Thermano system with a layer of construction-grade polyethylene film.

Thermano is ideal for the thermal insulation of flooring with underfloor heating systems, and is fully resistant to high temperatures.

5. The final step is the laying of the working surface of the flooring. This will protect the Thermano system, so that it lasts generations. Unlike legacy thermal insulation materials, the thermal insulating performance of PIR panels does not reduce over time.

When installing a Thermano thermal insulation system...

-

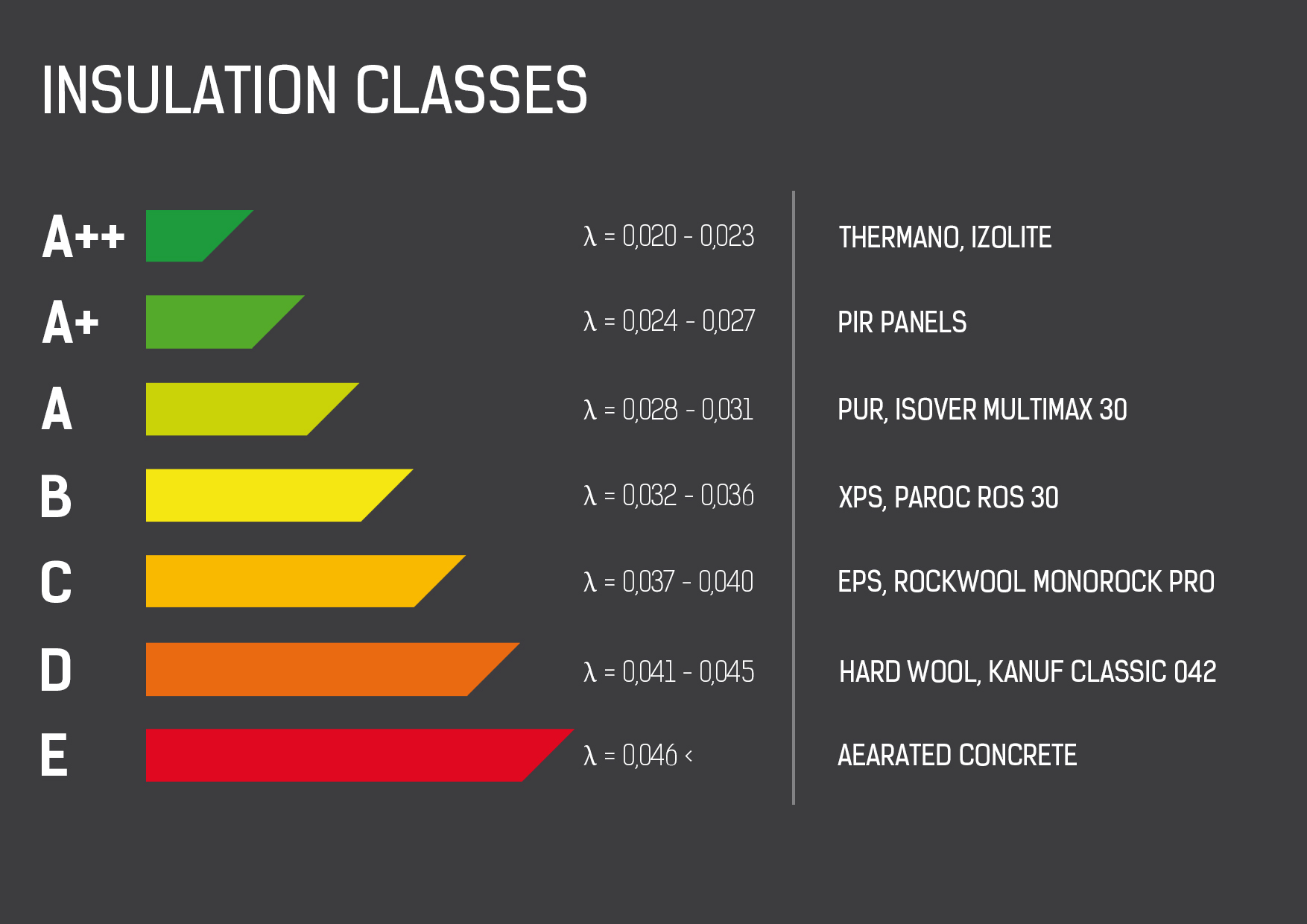

We get a floor layer thermally insulated with one of the best commercially available thermal insulators. By comparison, Thermano’s lambda, λ, value (or the thermal conductivity coefficient; lower is better) at 0.023 (W/mK), whereas the lambda of a quality XPS board is 0.031 (W/mK). This means that Thermano ensures a 50% improvement in the thermal insulating power.

-

We can install thermal insulation to last, for generations to come. Thermano is extremely durable, resistant to pressure and compression, impervious to damage from moisture, and retains its thermal insulating performance over the years.

-

The benefits of lower heating power consumption is immediate, improving how much we can save.

See more

-

Instructions for installing Thermano thermal insulation over the rafters of a sloping roof

-

Instructions for installing Thermano thermal insulation under the rafters of a sloping roof

- Instructions for installing Thermano on a green roof

-

Instructions for installing the Thermano thermal insulation system on a cavity wall

If you have any questions, please contact our Thermano technical consultants:

+48 801 000 807